This text is largely based on a Discourse post by Rhino user and teacher Lagom and enhanced with illustrations and examples.

Curves

In any CAD software, the accuracy and quality of your primary curves (“splines” or “sections” or “sketches”) is paramount, because they determine the quality of your primary surfaces, and your primary surfaces determine how well your secondary surfaces, and tertiary surfaces (blends, fillets) will work (think of a tree: “trunk > branch > twig > leaf” relationship).

Single span curves

Always try to use

![]() InterpCrv

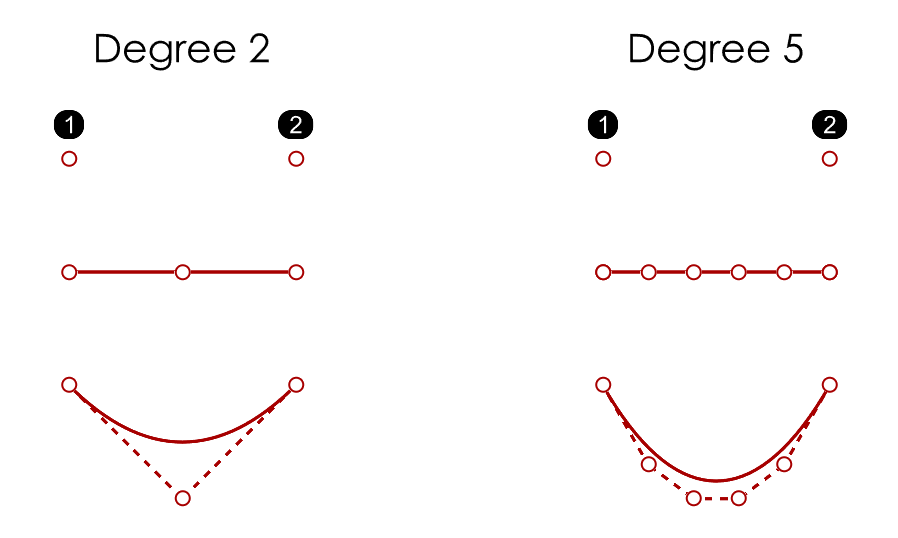

to draw single-span curves with Degree set to 2 or 5. Place the start and end points, then shape the curve by moving the 1 (degree 2) or 4 (degree 5) free controlpoints (CPs), or match them to other curves/surfaces directly.

InterpCrv

to draw single-span curves with Degree set to 2 or 5. Place the start and end points, then shape the curve by moving the 1 (degree 2) or 4 (degree 5) free controlpoints (CPs), or match them to other curves/surfaces directly.

Alternatively, use

![]() Curve

with Degree set to 2 or 5. Place the 3 (degree 2) or 6 (degree 5) CPs, then finalize the shape by moving them, or match it to other curves/surfaces directly.

There is a case when a degree 3 curve can be useful - for constructions where a single-span curve must “take off” with G2 and end in a point with G0 continuity.

Curve

with Degree set to 2 or 5. Place the 3 (degree 2) or 6 (degree 5) CPs, then finalize the shape by moving them, or match it to other curves/surfaces directly.

There is a case when a degree 3 curve can be useful - for constructions where a single-span curve must “take off” with G2 and end in a point with G0 continuity.

![]() BlendCrv

is ideal to create G1 (tangent) or G2 (curvature) continuous single span curves between existing curves and/or surface edges, allowing you to fine-tune their shape interactively (use the Show curvature option while doing so). Use the

key to change the contact angle. Use the

key to adjust symmetrically on both ends, while moving the G1 and G2 handles on one end.

BlendCrv

is ideal to create G1 (tangent) or G2 (curvature) continuous single span curves between existing curves and/or surface edges, allowing you to fine-tune their shape interactively (use the Show curvature option while doing so). Use the

key to change the contact angle. Use the

key to adjust symmetrically on both ends, while moving the G1 and G2 handles on one end.

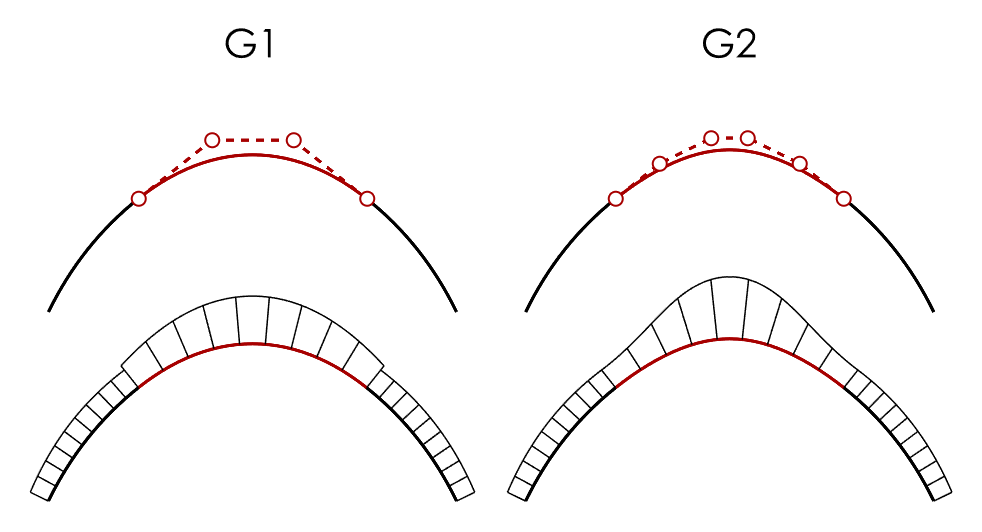

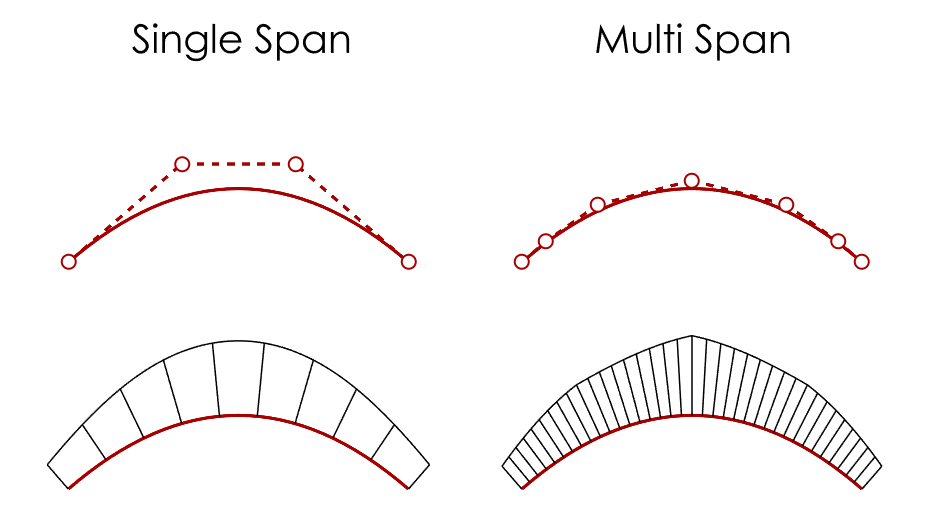

The advantage of using single span curves is that the curve is perfectly curvature continous internally. Curves that are multi-span, will have less fluent curvature transitions internally. When building surfaces from these curves, curvature irregularities between spans can become visible in the manufactured end result. The following image shows a single span degree 3 curve (4CPs) and a multispan degree 3 curve (7 CPs). Notice the G3 discontinuities in the multispan curve.

Circles

By default,

![]() Circle

creates a rational degree 2 curve with kinks (multi-knots). Draw circles with the Deformable option selected, Degree set to 5, and Point Count to 8. For ellipses, just non-proportionally scale (

Circle

creates a rational degree 2 curve with kinks (multi-knots). Draw circles with the Deformable option selected, Degree set to 5, and Point Count to 8. For ellipses, just non-proportionally scale (

![]() Scale1D

) such a circle.

Scale1D

) such a circle.

Editing Curves

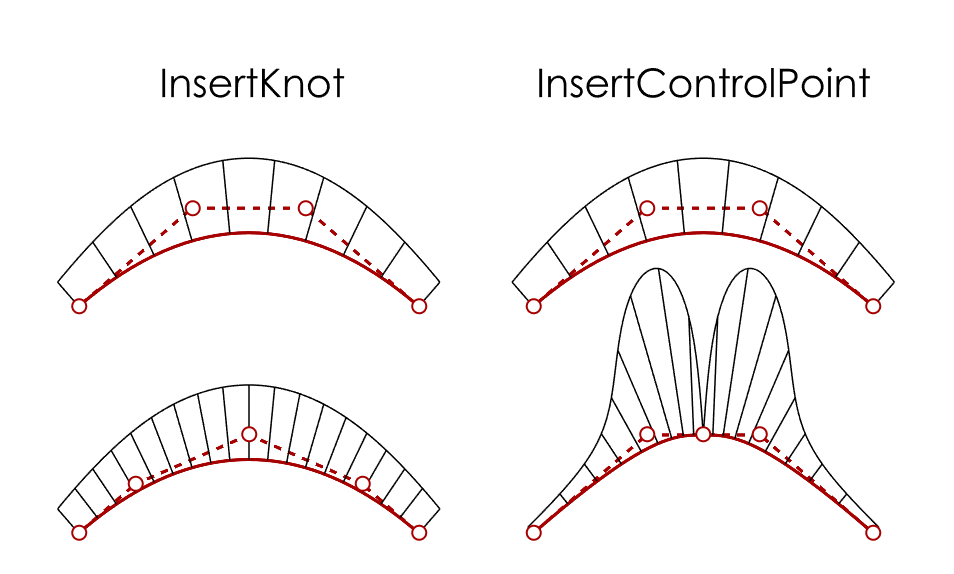

![]() InsertKnot

or

InsertKnot

or

![]() InsertControlPoint

can be used if you need an extra CP while shaping a curve. Both add a span and CP to the curve. InsertKnot adds a CP but keeps the shape of the curve the same, InsertControlPoint adds a CP and alters the shape of the curve. The following image shows the result of adding a knot or a CP at the middle of a degree 3 single span curve.

InsertControlPoint

can be used if you need an extra CP while shaping a curve. Both add a span and CP to the curve. InsertKnot adds a CP but keeps the shape of the curve the same, InsertControlPoint adds a CP and alters the shape of the curve. The following image shows the result of adding a knot or a CP at the middle of a degree 3 single span curve.

![]() RemoveKnot

removes a span and CP from the curve. The curve’s degree remains unchanged in both cases.

RemoveKnot

removes a span and CP from the curve. The curve’s degree remains unchanged in both cases.

Alternatively, use

![]() ChangeDegree

to a higher value with the Deformable option to add CPs to a curve. The number of spans and the curve’s shape remains unchanged. Caveat: without the Deformable option selected, more CPs will be created. Use the

ChangeDegree

to a higher value with the Deformable option to add CPs to a curve. The number of spans and the curve’s shape remains unchanged. Caveat: without the Deformable option selected, more CPs will be created. Use the

![]() CurvatureGraph

tool to see what happens.

CurvatureGraph

tool to see what happens.

![]() Rebuild

can be used to change a curve’s degree and number of CPs, but it is generally not recommended (messy CP structure).

Rebuild

can be used to change a curve’s degree and number of CPs, but it is generally not recommended (messy CP structure).

To flatten (planarise) one or more non-planar curves, select all CPs, click the Gumball X, Y or Z scaling icon, and type 0 into the value field. An alternative is using

![]() SetPt

macros, which can be assigned to aliases. These allow you to pick a point in the direction you are flattening. For example:

SetPt

macros, which can be assigned to aliases. These allow you to pick a point in the direction you are flattening. For example:

| Alias | Command Macro |

|---|---|

| sx | '_-setpt x=yes y=no z=no |

| sy | '_-setpt y=yes z=no x=no |

| sz | '_-SetPt z=yes x=no y=no |

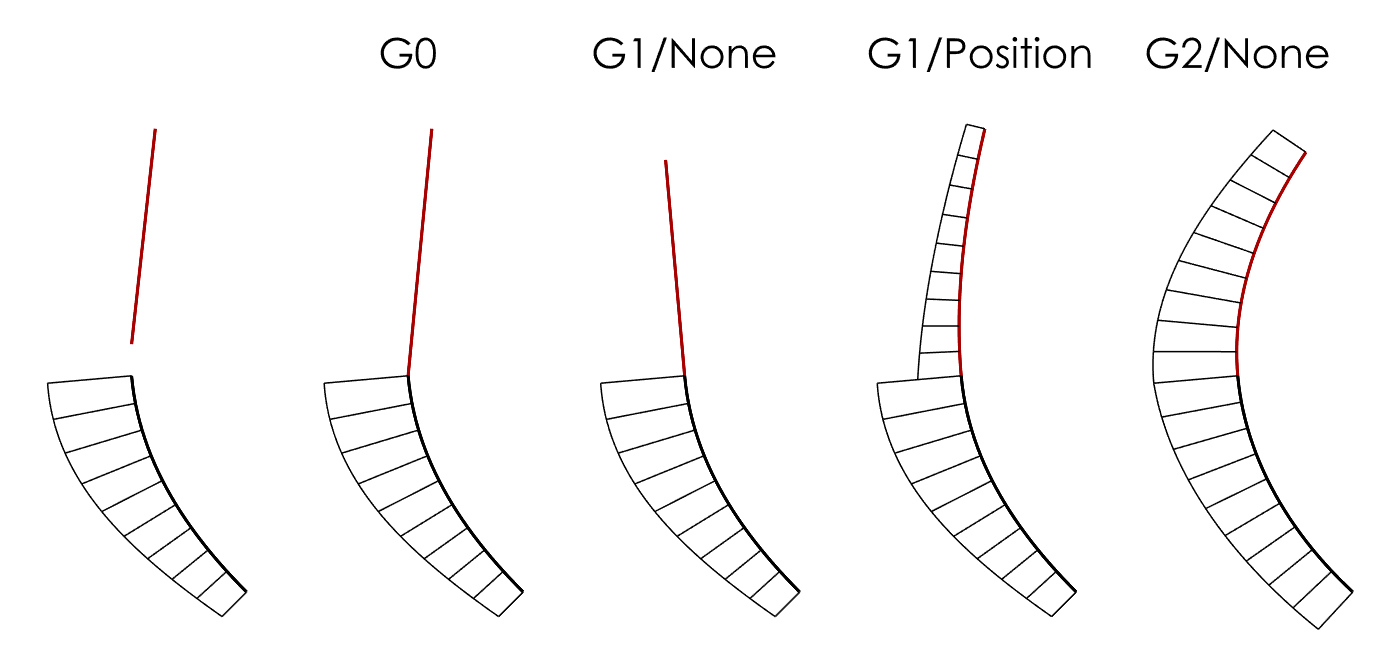

Curve Continuity

- Use

Match

to make a curve G0 (position), G1 (tangent) or G2 (curvature) continuous to another curve.

Match

to make a curve G0 (position), G1 (tangent) or G2 (curvature) continuous to another curve. - Use the SurfaceEdge option to match to any location on any surface edge, and the subsequent Perpendicular to edge option for a perfect “T” alignment.

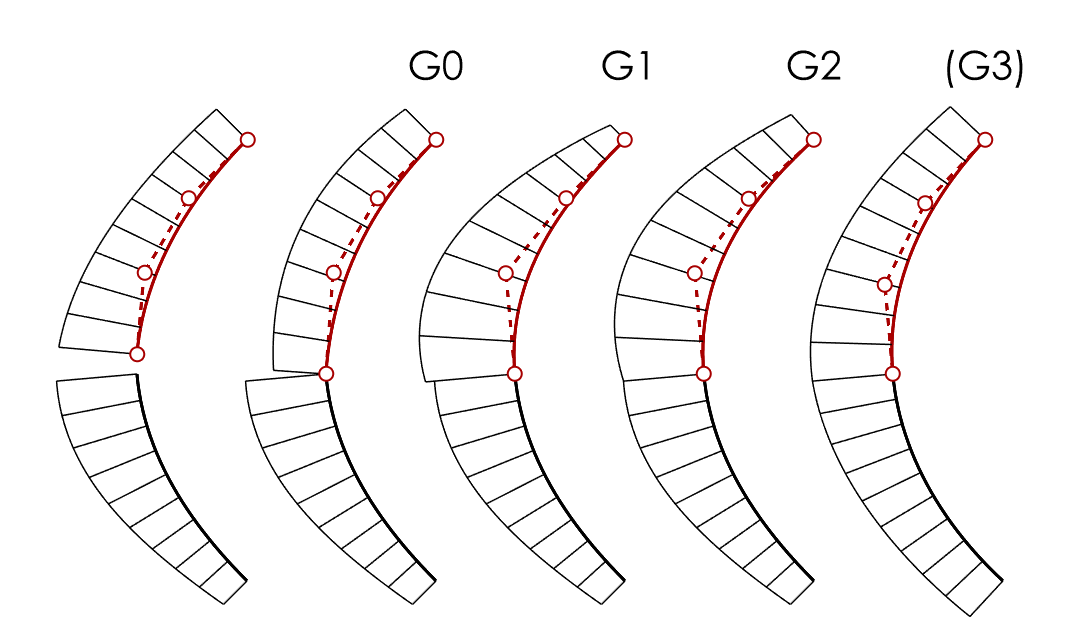

Although currently you cannot match curves with torsional continuity (G3) in Rhino, with help of point manipulation and curvature graph a close to G3 match can be made. Shown here is a match of the upper curve to the lower curve, while the end of the matched curve is preserved (positional).

EndBulge Curves

Use

![]() EndBulge

with the Tangency or Curvature option to manipulate the 2nd (G1) CP and/or 2nd and 3rd (G2) CPs to adjust the curve’s shape without losing the continuity previously established by matching. Activate

EndBulge

with the Tangency or Curvature option to manipulate the 2nd (G1) CP and/or 2nd and 3rd (G2) CPs to adjust the curve’s shape without losing the continuity previously established by matching. Activate

![]() CurvatureGraph

beforehand.

CurvatureGraph

beforehand.

Evaluating Curves

- Use

CurvatureGraph

to examine a curve’s curvature while modeling, and to check for internal G3 discontinuities.

CurvatureGraph

to examine a curve’s curvature while modeling, and to check for internal G3 discontinuities. - Use

GCon

to evaluate the G0 (position), G1 (tangent) or G2 (curvature) continuity between curves numerically. G0 continuity between curves is essential for building watertight (no naked edges) surface models.

GCon

to evaluate the G0 (position), G1 (tangent) or G2 (curvature) continuity between curves numerically. G0 continuity between curves is essential for building watertight (no naked edges) surface models.

Curve Do’s

Use single span curves whenever possible. Less spans/CPs mean that a curve’s curvature is easier to control. Also, simple curves make for simple surfaces.

Curve Don’ts

Don’t

![]() Join

curves (semi-circles joined to lines to build a “pill shape” is a classic), because joining creates kinks at the join location. When you use such curves to build surfaces, it can make subsequent operations unnecessarily difficult. Any design can be perfectly modeled without joining curves.

Join

curves (semi-circles joined to lines to build a “pill shape” is a classic), because joining creates kinks at the join location. When you use such curves to build surfaces, it can make subsequent operations unnecessarily difficult. Any design can be perfectly modeled without joining curves.

Surfaces

Editing Surfaces

By default, surfaces show two isocurves (one in the U and one in the V direction), if it is a single span surface. Set Isocurve Density to 0 in Properties to display only isocurves generated from a curve’s knots, or from an adjacent surface’ knots. In Rhino Options, General you can set the default to 0 as well if you prefer.

- You can use

RemoveKnot

to remove U and/or V isocurves to reduce surface complexity, and then use

RemoveKnot

to remove U and/or V isocurves to reduce surface complexity, and then use

ChangeDegree

.

ChangeDegree

. -

FitSrf

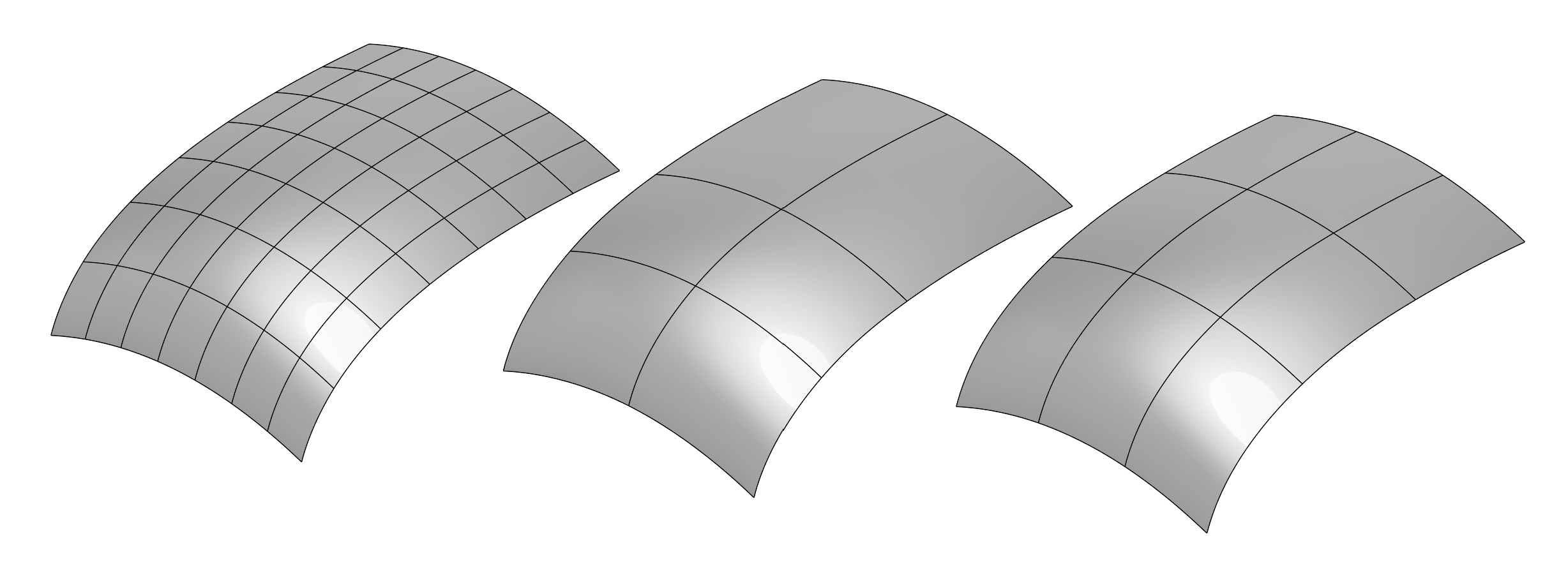

fits a surface based on set tolerance. This can be helpful to reduce the number of spans by changing the degree and choosing a tolerance. A Value of 0 will use your file’s absolute tolerance setting.

In this example, a dense surface patch (left) was Refit (middle) and Rebuilt (right) with roughly the same end tolerance result. You can see that FitSrf is more adaptive to the surface’ curvature as to where it places additional spans, which means that given a certain tolerance, it is capable of creating a simpler surface than Rebuild.

FitSrf

fits a surface based on set tolerance. This can be helpful to reduce the number of spans by changing the degree and choosing a tolerance. A Value of 0 will use your file’s absolute tolerance setting.

In this example, a dense surface patch (left) was Refit (middle) and Rebuilt (right) with roughly the same end tolerance result. You can see that FitSrf is more adaptive to the surface’ curvature as to where it places additional spans, which means that given a certain tolerance, it is capable of creating a simpler surface than Rebuild.

- To fine-tune a surface’ shape, use

DragMode

with the UVN option to adjust individual CPs. Set the Gumball to Align to Object. Adjust

DragMode

with the UVN option to adjust individual CPs. Set the Gumball to Align to Object. Adjust

DragStrength

if you want finer mouse control. You can also use the arrow keys on the keyboard for U and V movement, where for N movement, use

/

(On certain laptops :

plus

/

). Don’t forget to reset DragMode to normal by selecting the UVN option again after you’re done (it’s a toggle)!

DragStrength

if you want finer mouse control. You can also use the arrow keys on the keyboard for U and V movement, where for N movement, use

/

(On certain laptops :

plus

/

). Don’t forget to reset DragMode to normal by selecting the UVN option again after you’re done (it’s a toggle)! - Alternatively, use the traditional

MoveUVN

tool to improve continuity.

MoveUVN

tool to improve continuity. - To clean up a messy surface control point structure before matching for G1 or G2 continuity, this script by Pascal Golay is a life-saver, allowing you to planarise CPs along a surface’ U or V direction from any viewpoint. Save the script and run it from an alias (keyboard shortcut). For more info on running scripts, see this guide.

- In all cases, when modifying using controlpoint editing or fitting, check the continuity between your surfaces with

EdgeContinuity

EdgeContinuity

Cutting Surfaces

- Use

Trim

to cut off part of a surface with curves or other surfaces. The cut-off part is still “there”; it is just not displayed. Display the CPs

Trim

to cut off part of a surface with curves or other surfaces. The cut-off part is still “there”; it is just not displayed. Display the CPs

PointsOn

or keyboard shortcut

to see for yourself. See this page for more information about trimmed surfaces.

PointsOn

or keyboard shortcut

to see for yourself. See this page for more information about trimmed surfaces. - To cut a surface with another surface, while retaining the parts of both, use

Split

instead of Trim.

Split

instead of Trim. - To cut a surface in its U or V direction, use

Split

with the Isocurve option enabled. You can split freely or snap. The Shrink option creates two natural surfaces (display the CPs with/without Shrink and move one of the surfaces away to see what the difference is).

Split

with the Isocurve option enabled. You can split freely or snap. The Shrink option creates two natural surfaces (display the CPs with/without Shrink and move one of the surfaces away to see what the difference is). - Use

ExtendSrf

with a negative value and the Smooth and Merge options on to shorten a surface instead of using Split.

ExtendSrf

with a negative value and the Smooth and Merge options on to shorten a surface instead of using Split. -

RefitTrim

converts a surface with one trimmed edge (an edge-to-edge trim only) to an untrimmed (natural) surface, but it might deviate considerably from the original, so pay attention. Use

RefitTrim

converts a surface with one trimmed edge (an edge-to-edge trim only) to an untrimmed (natural) surface, but it might deviate considerably from the original, so pay attention. Use

MatchSrf

afterwards if previously achieved continuity to other surfaces must be re-established.

MatchSrf

afterwards if previously achieved continuity to other surfaces must be re-established. - Use

RebuildEdges

to “repair” trimmed edges that prevent proper matching.

RebuildEdges

to “repair” trimmed edges that prevent proper matching.

Surface Continuity

Use

![]() MatchSrf

to make a surface G0 (position), G1 (tangent) or G2 (curvature) continuous to another. You can only match untrimmed (natural) edges of a surface, but you can match to another surface’ trimmed edge. Click near the same end on both edges, so that the surface doesn’t flip. Always check with

MatchSrf

to make a surface G0 (position), G1 (tangent) or G2 (curvature) continuous to another. You can only match untrimmed (natural) edges of a surface, but you can match to another surface’ trimmed edge. Click near the same end on both edges, so that the surface doesn’t flip. Always check with

![]() EdgeContinuity

; don’t rely on the

EdgeContinuity

; don’t rely on the

![]() Zebra

display mode only.

Zebra

display mode only.

Recommendations when using

![]() MatchSrf

:

MatchSrf

:

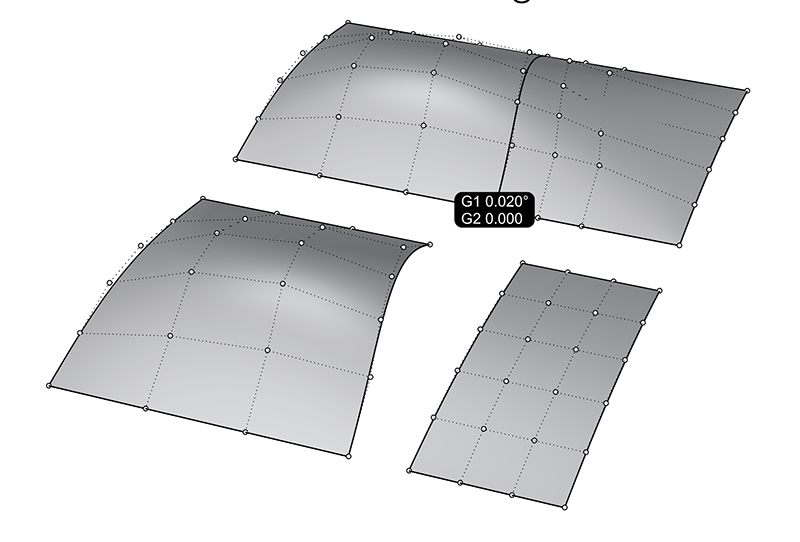

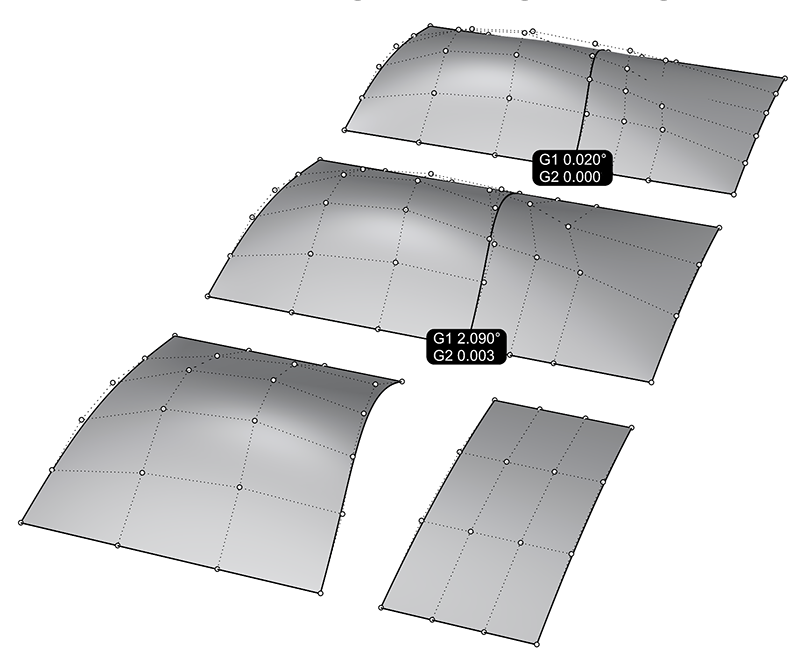

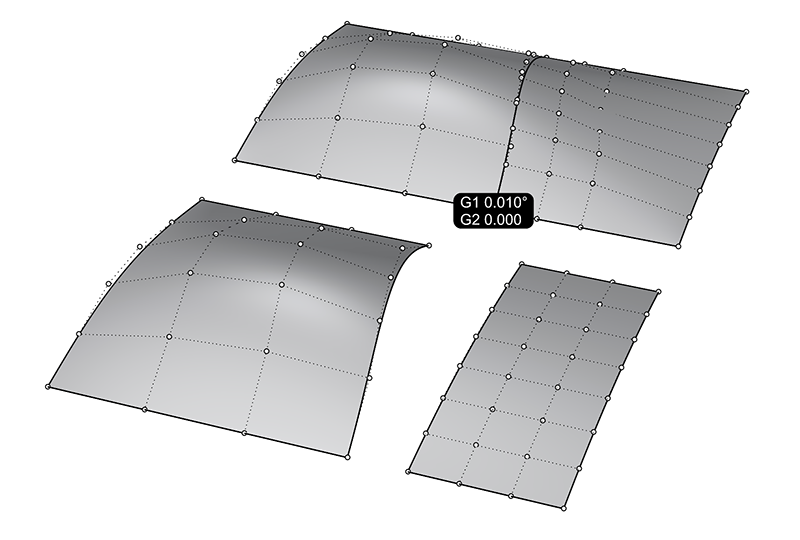

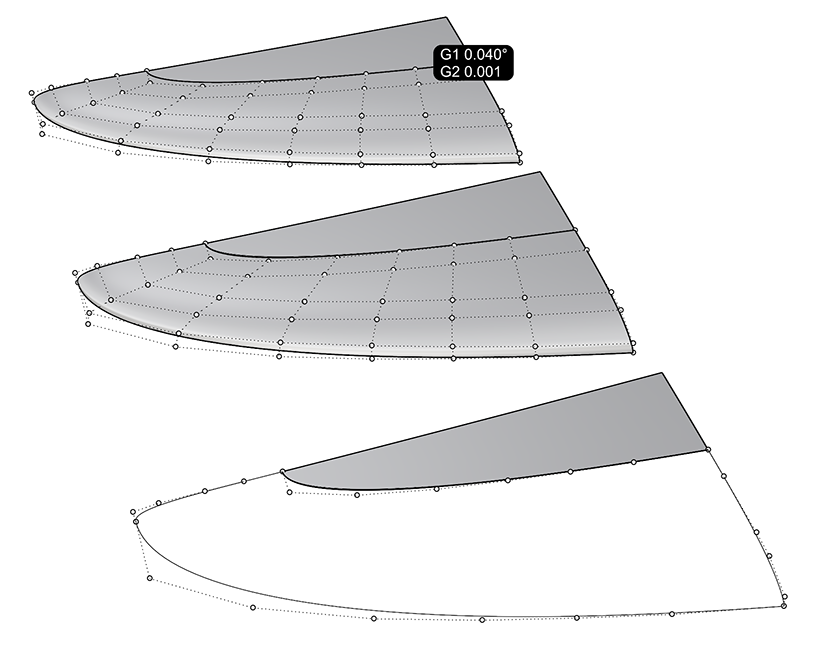

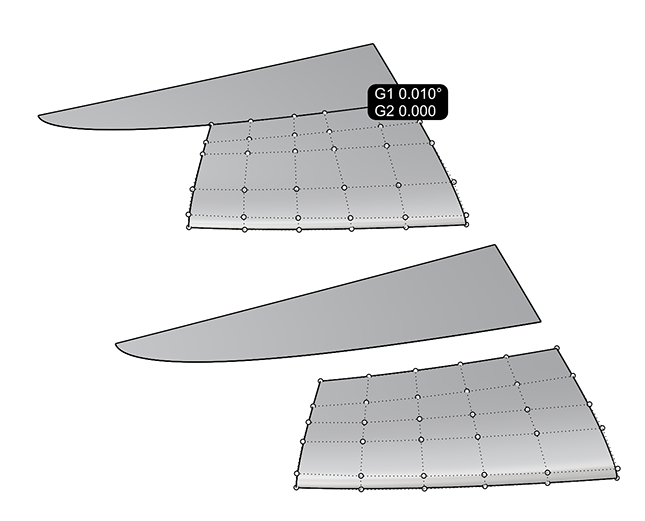

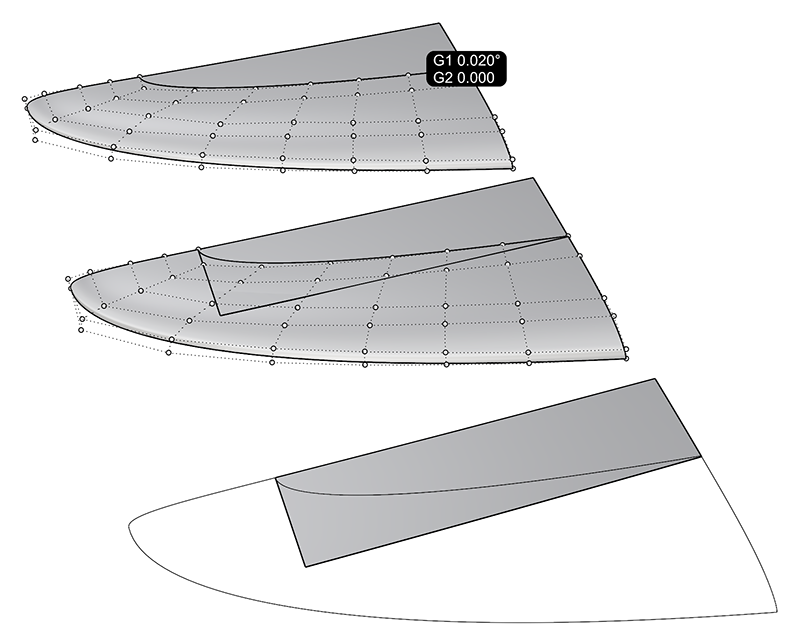

- Match equal degree surfaces: Use default options.

- Match a lower degree surface to a higher degree surface: Raise its degree with

ChangeDegree

before matching. The surfaces shown at the top in the image below are matching well after matching its degree to the target surface before running MatchSrf.

ChangeDegree

before matching. The surfaces shown at the top in the image below are matching well after matching its degree to the target surface before running MatchSrf.

- Match a higher degree surface to a lower degree surface: Use default options.

- Match a surface to a trimmed edge: Use the options Match edges by closest points and Preserve isocurve direction.

- Match a shorter surface edge to a longer surface edge (partial match): Use the option Match edges by closest points.

-

Match a surface while keeping its contact angle: Use the option Preserve isocurve direction.

-

Match a surface edge onto another surface: Use the On Surface option.

- The Average surfaces option equally changes both surfaces.

- The Refine match option often produces surfaces with far too many isocurves. Instead, turn on EdgeContinuity to find out where the largest deviation is, and insert a knot at that location with

InsertKnot

(try the Midpoints option) and match again. If you match with History enabled, the result of the analysis will update automatically after inserting a knot.

InsertKnot

(try the Midpoints option) and match again. If you match with History enabled, the result of the analysis will update automatically after inserting a knot.

To improve the result of MatchSrf, use

![]() DragMode

with the UVN option to adjust individual CPs. Set the Gumball to Align to Object.

Adjust

DragMode

with the UVN option to adjust individual CPs. Set the Gumball to Align to Object.

Adjust

![]() DragStrength

if you want finer mouse control. You can also use the arrow keys on the keyboard for U and V movement, where for N movement, you need to press the

plus

/

).

Don’t forget to reset DragMode to normal by choosing the UVN option again after you’re done (it’s a toggle)! Always check with EdgeContinuity.

DragStrength

if you want finer mouse control. You can also use the arrow keys on the keyboard for U and V movement, where for N movement, you need to press the

plus

/

).

Don’t forget to reset DragMode to normal by choosing the UVN option again after you’re done (it’s a toggle)! Always check with EdgeContinuity.

Alternatively, use the traditional

![]() MoveUVN

tool to improve continuity. Always check with EdgeContinuity.

MoveUVN

tool to improve continuity. Always check with EdgeContinuity.

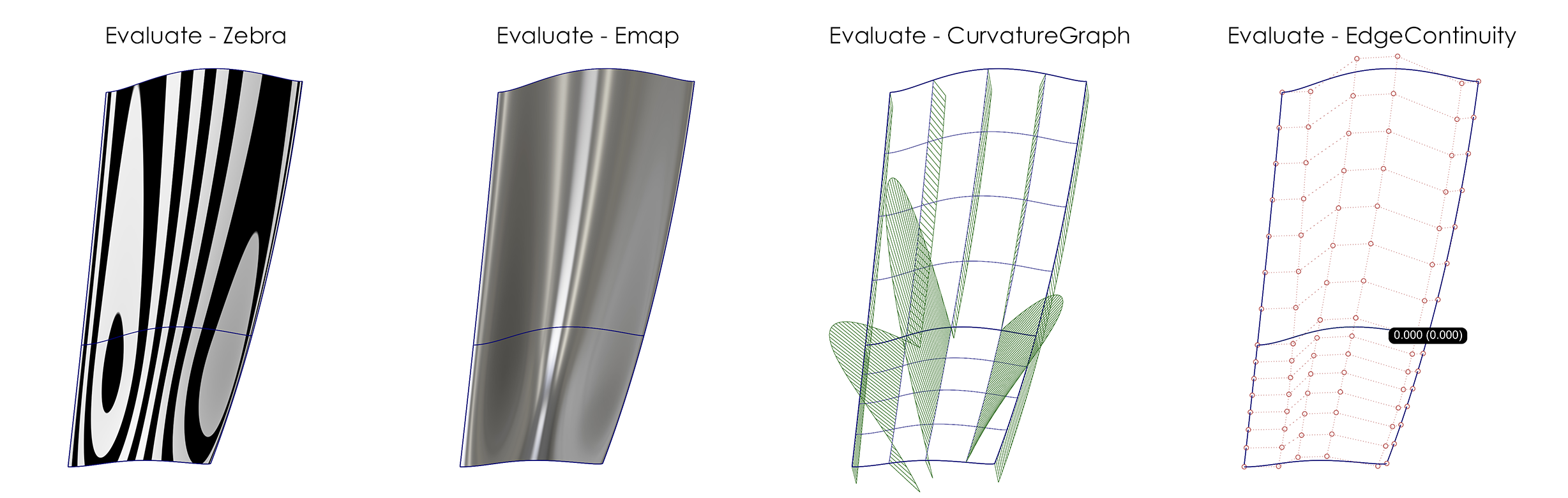

Evaluate surfaces visually

- Use

Zebra

with Adjust Mesh… and Simple Controls set to the highest polygon mesh density. Also consider using Detailed Controls to limit the Maximum edge length of polygons and Maximum angle for an even finer display. When examining the G1 or G2 continuity between surfaces, change between Horizontal and Vertical and tumble the view; also use the orthogonal views.

Zebra

with Adjust Mesh… and Simple Controls set to the highest polygon mesh density. Also consider using Detailed Controls to limit the Maximum edge length of polygons and Maximum angle for an even finer display. When examining the G1 or G2 continuity between surfaces, change between Horizontal and Vertical and tumble the view; also use the orthogonal views. - Use

Emap

to display a virtual environment reflected by your surfaces. You can also select your own spherical environment images.

Emap

to display a virtual environment reflected by your surfaces. You can also select your own spherical environment images. - To detect defects across and also inside of surfaces, use

CurvatureGraph

on one or more surfaces. Use Count to change the number of sections displayed. Select whether you want to analyse the U and/or V direction with Surface Hair.

CurvatureGraph

on one or more surfaces. Use Count to change the number of sections displayed. Select whether you want to analyse the U and/or V direction with Surface Hair.

Evaluate surfaces numerically

- Use

EdgeContinuity

to evaluate the G0, G1 or G2 continuity between surfaces numerically. G0continuity between curves is essential for building watertight (no naked edges) surface models.

EdgeContinuity

to evaluate the G0, G1 or G2 continuity between surfaces numerically. G0continuity between curves is essential for building watertight (no naked edges) surface models. - To display above-tolerance G0 gaps between the surfaces of your model (important for 3D printing and transfer to other CAD software), use

ShowEdges

with Naked Edges.

ShowEdges

with Naked Edges.

Surfacing Do’s

- Try to build single-span surfaces whenever possible. Simplify surfaces, or build simple surfaces in the first place.

- Use command

UseExtrusions

with Polysurface option to build normal Polysurfaces when you extrude. Default Rhino extrusions are simplified representations that make various surface modeling operations difficult later on.

UseExtrusions

with Polysurface option to build normal Polysurfaces when you extrude. Default Rhino extrusions are simplified representations that make various surface modeling operations difficult later on. - First build your large fillets, then build your small fillets, particularly when small fillets shall run over large fillets. For true radial G1 fillets, this script by Jim is a life-saver. Save the script and run it from an alias or keyboard shortcut.

- Use

Sweep2

preferably only when the rail curves have the same degree and number of CPs to avoid the creation of too many spans (and thus CPs). Otherwise, try

Sweep2

preferably only when the rail curves have the same degree and number of CPs to avoid the creation of too many spans (and thus CPs). Otherwise, try

RemoveMultiKnot

to remove multiple-knots, and re-match for possibly lost continuity.

RemoveMultiKnot

to remove multiple-knots, and re-match for possibly lost continuity. - Use

EdgeSrf

for full manual control (CP structure, continuity) on all four sides.

EdgeSrf

for full manual control (CP structure, continuity) on all four sides. - Use

BlendSrf

for controllable G1 and G2 blends between surface edges.

BlendSrf

for controllable G1 and G2 blends between surface edges. -

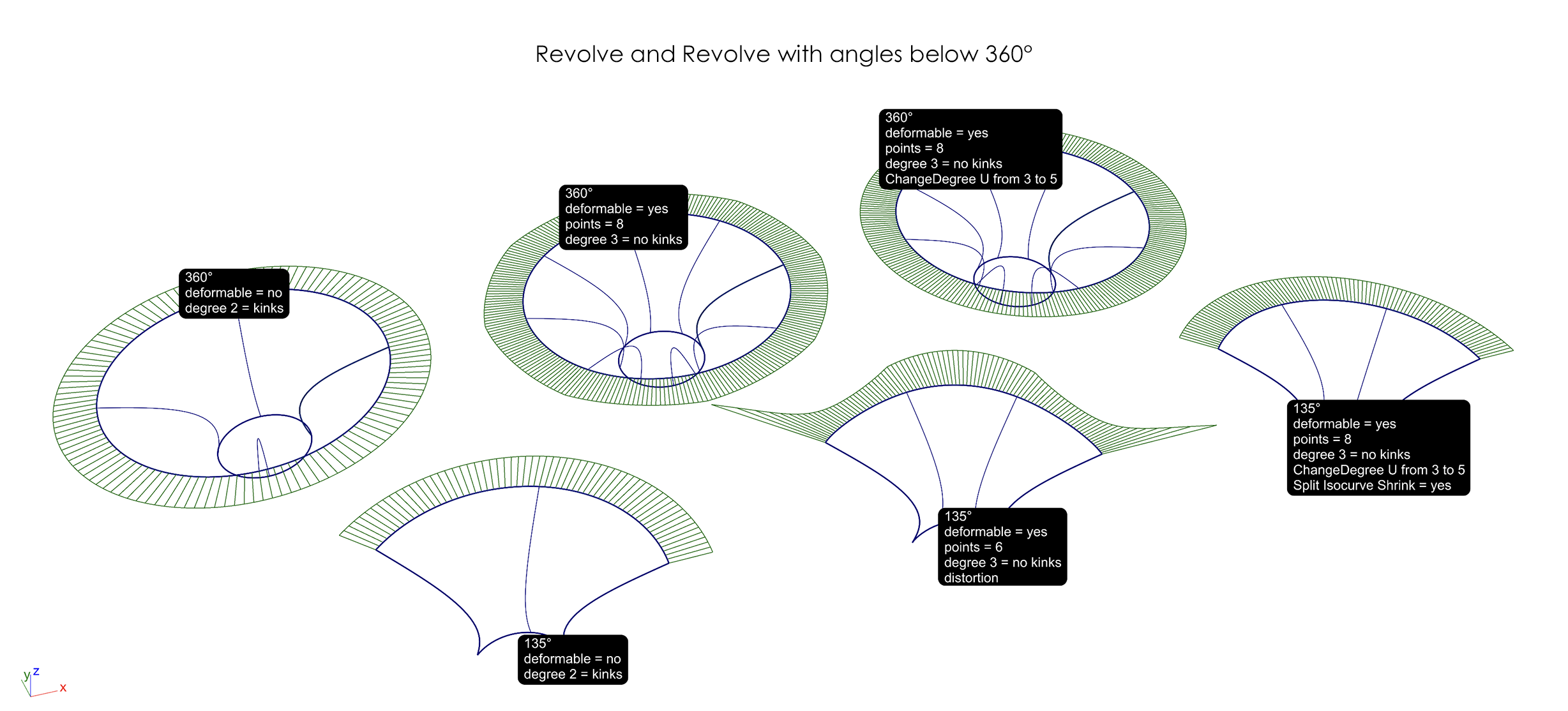

Revolve

360° with the Deformable option and Point Count 8 to obtain a degree 3 surface without kinks. Then

Revolve

360° with the Deformable option and Point Count 8 to obtain a degree 3 surface without kinks. Then

ChangeDegree

to 5 in the revolution’s orientation with the Deformable option. Revolving less than 360° is buggy, so revolve as above and then use

ChangeDegree

to 5 in the revolution’s orientation with the Deformable option. Revolving less than 360° is buggy, so revolve as above and then use

Split

using the Isocurve option to generate valid surfaces with smaller angles of revolution.

Split

using the Isocurve option to generate valid surfaces with smaller angles of revolution.

- Split revolved/periodic surfaces like cylinders, pipes, spheres, etc. in half with

Split

using the Isocurve option to eliminate the seam, or move the seam to an incongruous location with

Split

using the Isocurve option to eliminate the seam, or move the seam to an incongruous location with

SrfSeam

, so it cannot interfere with trimming and matching operations.

SrfSeam

, so it cannot interfere with trimming and matching operations. - Use

SplitEdge

on a “T” junction edge, when the surface edge you are building shall be shorter than the surface edge you are building to.

SplitEdge

on a “T” junction edge, when the surface edge you are building shall be shorter than the surface edge you are building to.

Surfacing Don’ts

- Don’t build your model using Rhino’s buggy solid modeling/boolean tools, and keep away from

FilletEdge

, which is inaccurate and can lead to all kinds of ugly problems downstream. Always use Rhino’s proper surface modeling tools, and join your surfaces into a solid for rendering, 3D printing, or CNC-machining at the very end.

FilletEdge

, which is inaccurate and can lead to all kinds of ugly problems downstream. Always use Rhino’s proper surface modeling tools, and join your surfaces into a solid for rendering, 3D printing, or CNC-machining at the very end. - Don’t build from trimmed edges, if you can avoid it, or to adjacent edges with too many isocurves arriving at that edge.

- Don’t build surfaces with three edges. Singularities (corners with a collapsed fourth surface edge of zero length) make filleting, matching, or joining very difficult or even impossible.

- Don’t use

Explode

after using

Explode

after using

Join

to test for naked edges while modeling. It permanently changes trimmed edges. Always use Undo instead.

Join

to test for naked edges while modeling. It permanently changes trimmed edges. Always use Undo instead. - Don’t use

Rebuild

, because it will almost always destroy your surface’s CP structure, and your surface might deviate substantially from adjacent surfaces.

Rebuild

, because it will almost always destroy your surface’s CP structure, and your surface might deviate substantially from adjacent surfaces. - Don’t use

NetworkSrf

(“notwork”) and

NetworkSrf

(“notwork”) and

Patch

(“botch”), as they create nothing but problems with continuity, filleting, and particularly UVN CP manipulation.

Patch

(“botch”), as they create nothing but problems with continuity, filleting, and particularly UVN CP manipulation.

MISCELLANEOUS

Curve and surface anatomy

To understand the fundamentals of NURBS curves and surfaces, see this Autodesk Alias page.

To understand the fundamentals of surface continuity, see this Autodesk Alias page.

To understand the fundamentals of curvature, see this Autodesk Alias page.

To display the knots/spans/isocurves - (ab)use InsertKnot, which temporarily displays them (click Cancel right after). Please note: Rhino’s EditPtOn shows you the “Greville points”, not the knots (in Alias, the knots are called “edit points”). Consider setting the Isocurve Density to 0 in Settings… (Options in Windows) > General, so only “real” isocurves are shown (unless you need extra isocurves for snapping, or other modeling tasks). Alternatively, use CurvatureGraph and set Density to 0; a hair will be shown at each knot.